PCB Printing

PCB Printing: Professional Screen Printing Solutions for Printed Circuit Board IndustryPCB screen printing is acore

Detail Description

PCB Printing: Professional Screen Printing Solutions for Printed Circuit Board Industry

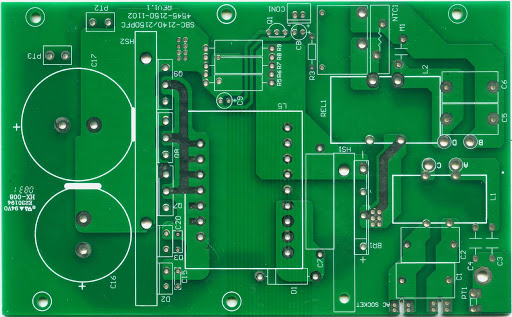

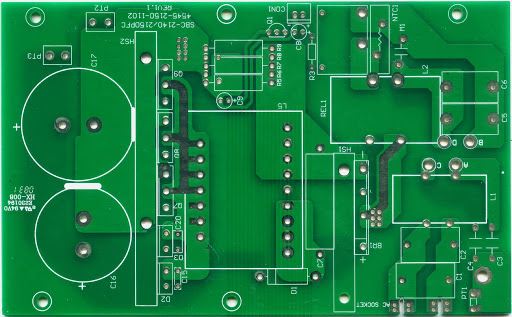

PCB screen printing is a core process in electronic component manufacturing that undertakes the critical task of applying solder paste or conductive ink to the surface of printed circuit boards. With its high precision, stable ink adhesion, and compatibility with various PCB substrates, professional screen printing technology provides reliable process support for the mass production of rigid PCBs, flexible PCBs (FPC), and rigid-flex PCBs, ensuring the stable operation of electronic products.

I. Core Application Scenarios

Solder Paste Printing for PCB Assembly

The most fundamental and critical application in PCB manufacturing. By precisely printing solder paste onto the pad areas of PCBs through high-precision screens, it provides the necessary bonding medium for the subsequent surface mount technology (SMT) chip placement and reflow soldering processes. Suitable for consumer electronics (mobile phones, computers), automotive electronics, industrial control boards, and other high-density PCB production, with printing accuracy up to ±0.02mm to meet the requirements of fine-pitch components.

Conductive Ink Printing for Circuit Fabrication

Targeting the production of flexible circuits, thick-film circuits, and RFID antenna boards, special conductive inks (silver paste, copper paste, carbon paste) are printed onto insulating substrates (PI, PET, ceramic) to form conductive circuits, electrodes, or resistance layers. This process features low cost, high production efficiency, and good compatibility with flexible substrates, and is widely used in wearable devices, smart labels, and automotive sensor circuits.

Protective & Functional Ink Printing

Includes the printing of solder mask ink and character ink. Solder mask ink printing covers the non-pad areas of PCBs to protect the copper foil from oxidation, prevent short circuits between circuits, and enhance the corrosion resistance of the board. Character ink printing marks component models, polarities, and board numbers on the PCB surface, facilitating subsequent assembly, inspection, and maintenance.

Special Process Printing for High-End PCBs

For high-frequency communication boards, automotive-grade PCBs, and aerospace PCBs, specialized screen printing processes are provided, such as printing of electromagnetic shielding ink, thermal conductive ink, and high-temperature resistant ink. These special inks help PCBs achieve functions such as anti-interference, heat dissipation, and high-temperature resistance, meeting the extreme environment application requirements of electronic products.II. Process Advantages & Technical Highlights

Ultra-High Printing Precision

Adopting high-precision CNC screen making technology, combined with visual alignment systems and automatic printing equipment, it can achieve fine line width/space printing of 0.1mm or less, matching the assembly needs of micro-miniature components in modern electronic products.

Excellent Ink Adhesion & Uniformity

The screen printing process can control the thickness of the ink layer accurately (from a few microns to dozens of microns), ensuring uniform ink coverage on the PCB surface. The printed ink layer has strong adhesion, which can withstand high-temperature reflow soldering, chemical cleaning, and mechanical vibration without peeling or falling off.

Strong Compatibility with Substrates & Inks

Compatible with various PCB substrates, including FR-4, aluminum substrate, ceramic substrate, PI film, etc. It can adapt to different types of functional inks (solder paste, conductive ink, solder mask ink) and realize one-stop printing of multiple processes on a single production line.

Cost-Effective for Mass Production

Compared with inkjet printing and laser etching processes, screen printing has lower equipment and consumables costs. For large-batch PCB production, it can significantly reduce the unit processing cost while ensuring stable product quality, which is the first choice for cost-sensitive electronic manufacturing enterprises.III. Industry Compliance & Quality Assurance

Strict Compliance with Industry Standards

All printing materials and processes comply with IPC (Association Connecting Electronics Industries) standards, including IPC-6012 (Qualification and Performance Specification for Rigid Printed Boards) and IPC-CC-830 (Qualification and Performance Specification for Solder Mask). The printed PCBs meet RoHS, REACH, and other environmental protection requirements, suitable for export to international markets.

Full-Process Intelligent Quality Control

Equipped with automatic optical inspection (AOI) equipment, which conducts 100% inspection on the printing position accuracy, ink layer thickness, and defects (missing printing, offset, blurring) after printing. Combined with offline sampling testing such as solder paste viscosity detection and ink adhesion testing, it ensures that the pass rate of each batch of products meets the customer's requirements.

Clean Production Environment

The PCB printing workshop adopts a dust-free purification design (Class 10000 or above) to avoid dust particles from contaminating the PCB surface and affecting printing quality. Temperature and humidity are precisely controlled to ensure the stability of ink and solder paste performance during the printing process.IV. Service Process

Pre-Processing Technical Communication: According to the customer's PCB design drawings, substrate type, and functional requirements, provide customized printing scheme design, including screen making parameters, ink selection, and process flow formulation.

Proofing & Testing: Produce small-batch samples, conduct performance tests such as solder paste spreading rate, conductive resistance, and ink adhesion, and confirm the sample quality with the customer before mass production.

Mass Production & Traceability: Carry out automated mass printing production, and record key process parameters (printing pressure, speed, temperature) in real time to realize full-process product traceability.

Quality Inspection & Delivery: After AOI full inspection and manual sampling review, carry out vacuum packaging of finished PCBs to prevent oxidation, and provide third-party testing reports as required to ensure on-time delivery.

Our PCB screen printing solutions rely on precision equipment, professional technology, and strict quality control to help electronic manufacturing enterprises improve production efficiency, reduce costs, and enhance the reliability of PCB products, creating greater value for the development of the electronics industry.

Interested in this solution?

Our experts are ready to discuss how our screen mesh solutions can optimize your PCB Printing process.